Cleanroom Construction Newsletter

Understanding Cleanroom Design and Construction Requirements

Don’t Do It Yourself

(Click on thumbnail to enlarge)

If you browse through any bookstore, you will notice a large section devoted to “Do It Yourself” books on many and various subjects. While this is a current rage, magnified by the poor state of the economy, there are still some projects best left to the experts.

Cleanroom design and construction comes to mind as one of those projects. This is an engineering specific field that does not fit well with the “Do It Yourself” format, unless you are already a qualified cleanroom designer and cleanroom construction manager, such as Liberty Industries, Inc.

The Cleanroom project must be coordinated from start to finish, or disaster may ensue. There needs to be one single, well qualified cleanroom company to integrate and coordinate the entire process and take responsibility for the final outcome to ensure a successful project.

The chosen company must demonstrate a full working knowledge of cleanroom principles, procedures, materials, and practices. Of highly significant importance, the chosen company must have a full understanding of the heating, ventilating, and air conditioning (HVAC) design process and the specialized HVAC equipment involved in maintaining space conditions of temperature, humidity, and pressure within the cleanroom.

(Click on thumbnail to enlarge)

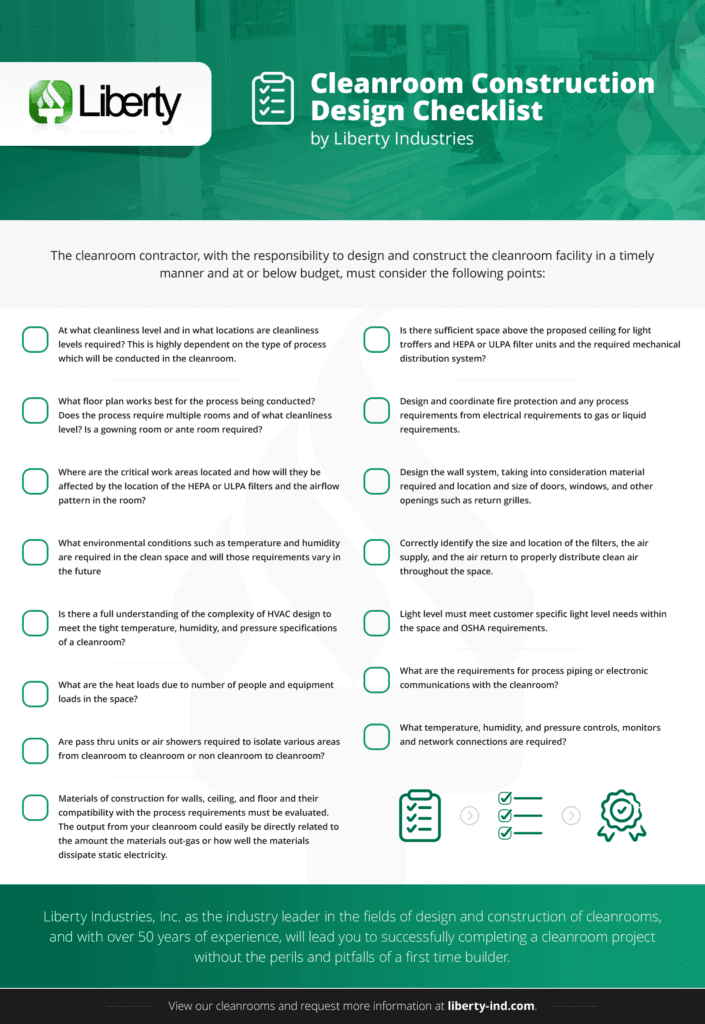

The aim of the cleanroom contractor must be to provide a complete facility with minimum participation by the customer or end user. The cleanroom contractor, with the responsibility to design and construct the cleanroom facility in a timely manner and at or below budget, must consider the following points:

- At what cleanliness level and in what locations are cleanliness levels required? This is highly dependent on the type of process which will be conducted in the cleanroom.

- What floor plan works best for the process being conducted? Does the process require multiple rooms and of what cleanliness level? Is a gowning room or ante room required?

- Where are the critical work areas located and how will they be affected by the location of the HEPA or ULPA filters and the airflow pattern in the room?

- What environmental conditions such as temperature and humidity are required in the clean space and will those requirements vary in the future?

- Is there a full understanding of the complexity of HVAC design to meet the tight temperature, humidity, and pressure specifications of a cleanroom?

- What are the heat loads due to number of people and equipment loads in the space?

- Are pass thru units or air showers required to isolate various areas from cleanroom to cleanroom or non cleanroom to cleanroom?

- Materials of construction for walls, ceiling, and floor and their compatibility with the process requirements must be evaluated. The output from your cleanroom could easily be directly related to the amount the materials out-gas or how well the materials dissipate static electricity.

- Is there sufficient space above the proposed ceiling for light troffers and HEPA or ULPA filter units and the required mechanical distribution system?

- Design and coordinate fire protection and any process requirements from electrical requirements to gas or liquid requirements.

- Design the wall system, taking into consideration material required and location and size of doors, windows, and other openings such as return grilles.

- Correctly identify the size and location of the filters, the air supply, and the air return to properly distribute clean air throughout the space.

- Light level must meet customer specific light level needs within the space and OSHA requirements.

- What are the requirements for process piping or electronic communications with the cleanroom?

- What temperature, humidity, and pressure controls, monitors and network connections are required?

(Click on thumbnail to enlarge)

The customer or end user must ensure that the cleanroom contactor can engineer, design, and fabricate the facility with a high degree of quality, on time, and at budget. The cleanroom contractor must be in a position to warranty the room for one (1) year from start-up and guarantee the facility’s compliance with the latest I.E.S. Recommended Practices through independent testing and certification.

Liberty Industries, Inc. as the industry leader in the fields of design and construction of cleanrooms, and with over 50 years of experience, will lead you to successfully completing a cleanroom project without the perils and pitfalls of a first time builder. Don’t get comfortable with a “Do it Yourself” approach as you will end up underperforming, over budget, and beyond a predicted time line.