Cleanrooms

(Click on thumbnail to enlarge)

Cleanrooms provide clean environments in which manufacturers build highly sensitive electronic, pharmaceutical, and similar products. Diverse industrial operations use these enclosed environments to control humidity, temperature, pressure, and other environmental parameters that can compromise mechanically or biologically sensitive products.

Manufacturers in the biotech, medical device, pharmaceutical, life science, aerospace, and military fields build cleanrooms of various sizes and complexities to control the movement of small particles that can disrupt operations. In these rooms, airlocks seal the environment from outside influences and provide an area for personnel to decontaminate while entering and exiting.

Air showers, gowning rooms, and other intermediate compartments also allow for the storage of special equipment and clothing needed in the environment. Specialized garments allow cleanroom personnel to navigate environments without leaving behind traces of body matter that can contaminate some industrial processes.

Cleanroom Classifications

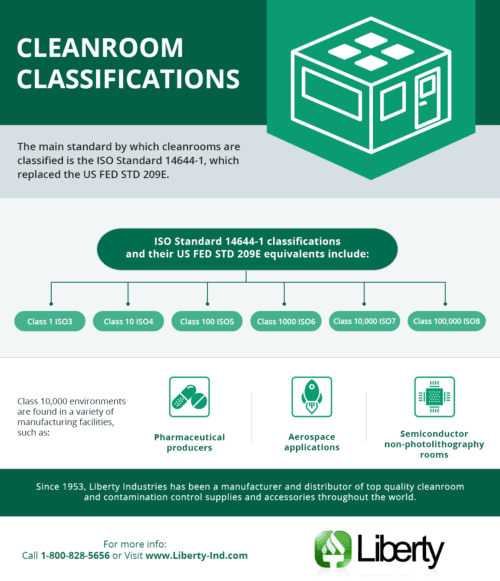

Cleanrooms are designed according to the unique needs of the manufacturer. Classifications describe the number and size of particles per volume of air allowed within the environment. There are two main standards by which cleanrooms are classified: the ISO Standard 14644-1 and the US FED STD 209E. Both are similar, but they’re encountered in different industries.

The US FED STD 209E defines six cleanroom classes. This standard measures the number of particles in each cubic foot of air that are 0.5 µm or higher in size. Cleanrooms that conform to these standards deliver at least 45–60 air changes per hour.

US FED STD 209E classifications and their ISO Standard 14644-1 equivalents include:

- Class 1 ISO3

- Class 10 ISO4

- Class 100 ISO5

- Class 1000 ISO6

- Class 10,000 ISO7

- Class 100,000 ISO8

Class 10,000 environments are found in a variety of manufacturing facilities, such as:

- Pharmaceutical producers

- Aerospace applications

- Semiconductor non-photolithography rooms

The construction of each cleanroom includes elements that limit exposure to potentially harmful particles, reduce interaction with outside environments, and keep the internal air quality within the required parameters. Some of these elements include:

- Air-locked gowning rooms

- Pass-throughs for products and equipment

- Hands-free stainless steel sinks

- Heat-welded vinyl or epoxy floors

- Gown racks and equipment storage

- Fully operational HVAC systems

- Fans with HEPA filters (Fan Filter Units)

- Sealed lighting

- Air pressure monitoring

- Stainless steel seating benches

- Laminar flow benches

Tacky Mats® located at the entrance and exit of the cleanroom keep dust and dirt from infiltrating the sealed environment. Workers are usually required to wear suits, booties, and caps to reduce the number of skin flakes and other body particles in the environment. For some sensitive applications, an air shower is included at the entrance for entrants to scrub away potential contaminants.

Liberty Industries builds a number of cleanrooms for use in a variety of manufacturing and laboratory environments. Our offerings include:

VFCS-3 Cleanroom – Vertical Flow Component System

A modular cleanroom, our Vertical Flow Component System (VCFS) has the quickest installation times on the market today. These cleanrooms and isolation enclosures are used in a variety of industries, including:

- Medical equipment manufacturing

- Assembly and packaging

- Electronics assembly

- Aerospace

- Computers

- Research

- Food preparation and processing

- Pharmaceutical manufacturing

These cleanrooms come with an innovative latching system that makes it virtually effortless to attach panels together. Additionally, roof panels offer users the ability to insert custom features such as HEPA filters or drop-in light fixtures. These cleanrooms include window panels made from durable clear 1/8” Plexiglass, and their lightweight design makes assembly easy.

Softwall Cleanroom (SIS) – Softwall Isolation System

These heavy-duty cleanrooms use 2.125” × 2.125” square, 6063-T-5 extruded aluminum frameworks to provide an extra layer of protection from external elements. They include ceiling frames constructed from 1” square, 6063-T-5 extruded aluminum as well as perimeter frames integrated with a 2” T-grid cross bar system, which incorporates a fully gasketed opening for HEPA modules, lights, and ceiling tiles.

Additional features of these cleanrooms include:

- Liberty’s MAC10 Series 2 × 4 motorized fan filter modules with pre-filters

- Class 100 ceiling panels

- 100–125 FTC lights inside enclosures

- Vinyl curtains of 40 mm solid

- 7.5” high frames with leg levelers

Modular Hard-Wall or Soft-Wall Cleanrooms

Liberty’s 7300-series modular cleanrooms are designed with hard-wall, soft walls, or hard acrylic walls and include a number of customization options that enable them to fit a range of unconventional or restricted space requirements.

7300-series modular cleanrooms with modular hard wall materials feature an anodized and extruded aluminum framework. The modular hard wall panels themselves are constructed from aluminum sheets with a polyester finish, contain a thermoplastic HDPE core, and are mounted on the existing gypsum wall board.

Other options and features include:

- Flush-mounted safety glass windows

- Self-supported cleanroom ceiling grid, including options such as:

-

- 1.5” Anodized aluminum self-supported finish on gasketed extruded aluminum

- Basic 2’ x 4’ grid layout except determined by final design, suspended by suspension wire to existing building structure

- ISO 5 white aluminum-faced cleanroom rated ceiling tiles.

- Elevation of ceiling height no less than 8’above finished floor

- Liberty’s MAC10 Series 2’ x 4’ motorized fan filter modules with pre-filters

- Class 100 ceiling panels

- 100–125 FTC lights inside ISO Standard 14644-1

-

This cleanroom is designed to meet or exceed USP <797> and USP <800> requirements and may also include anterooms as needed, and also meets ISO Standard 14644-1. As a versatile and modular cleanroom, it is also available in a full range of classifications, including:

- Class 1 ISO3

- Class 10 ISO4

- Class 100 ISO5

- Class 1000 ISO6

- Class 10,000 ISO7

- Class 100,000 ISO8

Create Quick Custom Cleanrooms with Liberty Industries

Liberty Industries partners with manufacturers from a variety of industries to create cleanrooms that conform to our clients’ preferred standards. Choose a standard-sized enclosure or work with our team to customize a design that fits your vision.

Our options include hard- and soft-wall models that are also available in modular or portable versions. Our team assists with HVAC design, engineering, and installation. We can also serve as expert consultants on your private project. Our cleanrooms are the perfect solution for manufacturers in industries ranging from:

- Pharmaceutical

- Medical device

- Aerospace/government

- Healthcare

- Research labs

- Animal labs

- Precision manufacturing

- Metal and lead

- Electronics

- Semiconductors

- Optical

- Hospital/pharmacy

- Automotive

- University

- Injection molding

- Plastics

- Laboratory

- Ball bearings

- Printed circuits

- Computer rooms

- Nanotech

Beyond designing and building custom cleanrooms, Liberty Industries supplies manufacturers with accessories that increase the effectiveness of their sealed environments. We also build a full range of cleanroom accessories, including lab supplies, flow equipment, Tacky Mats®, and shoe brush machines to help you control the passage of particles in specialized production facilities.

Cleanrooms allow manufacturers to produce safe and high-quality products while reducing health risks to personnel. View our online catalog to learn more about our custom cleanroom options and services, and be sure to contact us today if you’re interested in requesting a quote.

** Tacky Mat® is a registered trademark to Liberty Industries.