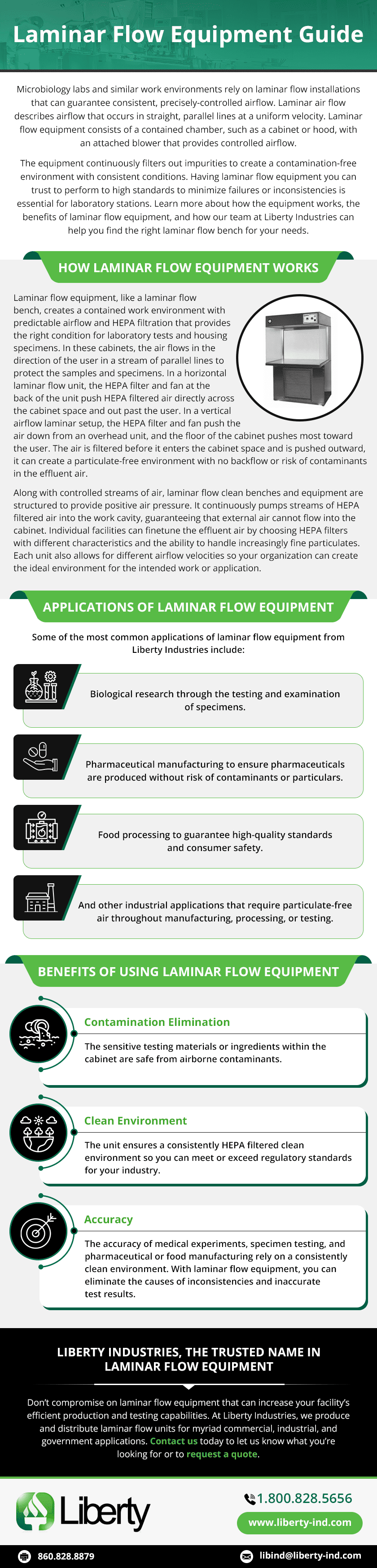

Laminar Flow Equipment Guide

Microbiology labs and similar work environments rely on laminar flow installations that can guarantee consistent, precisely-controlled airflow. Laminar air flow describes airflow that occurs in straight, parallel lines at a uniform velocity. Laminar flow equipment consists of a contained chamber, such as a cabinet or hood, with an attached blower that provides controlled airflow.

The equipment continuously filters out impurities to create a contamination-free environment with consistent conditions. Having laminar flow equipment you can trust to perform to high standards to minimize failures or inconsistencies is essential for laboratory stations. Learn more about how the equipment works, the benefits of laminar flow equipment, and how our team at Liberty Industries can help you find the right laminar flow bench for your needs.

How Laminar Flow Equipment Works

Laminar flow equipment, like a laminar flow bench, creates a contained work environment with predictable airflow and HEPA filtration that provides the right condition for laboratory tests and housing specimens. In these cabinets, the air flows in the direction of the user in a stream of parallel lines to protect the samples and specimens. In a horizontal laminar flow unit, the HEPA filter and fan at the back of the unit push HEPA filtered air directly across the cabinet space and out past the user. In a vertical airflow laminar setup, the HEPA filter and fan push the air down from an overhead unit, and the floor of the cabinet pushes most toward the user. The air is filtered before it enters the cabinet space and is pushed outward, it can create a particulate-free environment with no backflow or risk of contaminants in the effluent air.

Along with controlled streams of air, laminar flow clean benches and equipment are structured to provide positive air pressure. It continuously pumps streams of HEPA filtered air into the work cavity, guaranteeing that external air cannot flow into the cabinet. Individual facilities can finetune the effluent air by choosing HEPA filters with different characteristics and the ability to handle increasingly fine particulates. Each unit also allows for different airflow velocities so your organization can create the ideal environment for the intended work or application.

Applications of Laminar Flow Equipment

Some of the most common applications of laminar flow equipment from Liberty Industries include:

- Biological research through the testing and examination of specimens

- Pharmaceutical manufacturing to ensure pharmaceuticals are produced without risk of contaminants or particulars

- Food processing to guarantee high-quality standards and consumer safety

- And other industrial applications that require particulate-free air throughout manufacturing, processing, or testing

Benefits of Using Laminar Flow Equipment

Laminar flow equipment is essential for any operation that demands air quality control and a particulate-free environment for processing or inspecting materials. The benefits of these units include:

- Contamination Elimination: The sensitive testing materials or ingredients within the cabinet are safe from airborne contaminants.

- Clean Environment: The unit ensures a consistently HEPA filtered clean environment so you can meet or exceed regulatory standards for your industry.

- Accuracy: The accuracy of medical experiments, specimen testing, and pharmaceutical or food manufacturing rely on a consistently clean environment. With laminar flow equipment, you can eliminate the causes of inconsistencies and inaccurate test results.

Liberty Industries, the Trusted Name in Laminar Flow Equipment

Don’t compromise on laminar flow equipment that can increase your facility’s efficient production and testing capabilities. At Liberty Industries, we produce and distribute laminar flow units for myriad commercial, industrial, and government applications. Contact us today to let us know what you’re looking for or to request a quote.