Aerospace Cleanrooms

The aerospace industry relies on specially designed cleanrooms for manufacturing reliable, safe, high-quality parts without defects. Understanding what requirements your cleanroom must adhere to and the various types of equipment available for cleanroom environments can help you select the right options for your facility. At Liberty Industries, we provide compliant modular and softwall cleanrooms, equipment, and an array of accessories and supplies to support our aerospace clients.

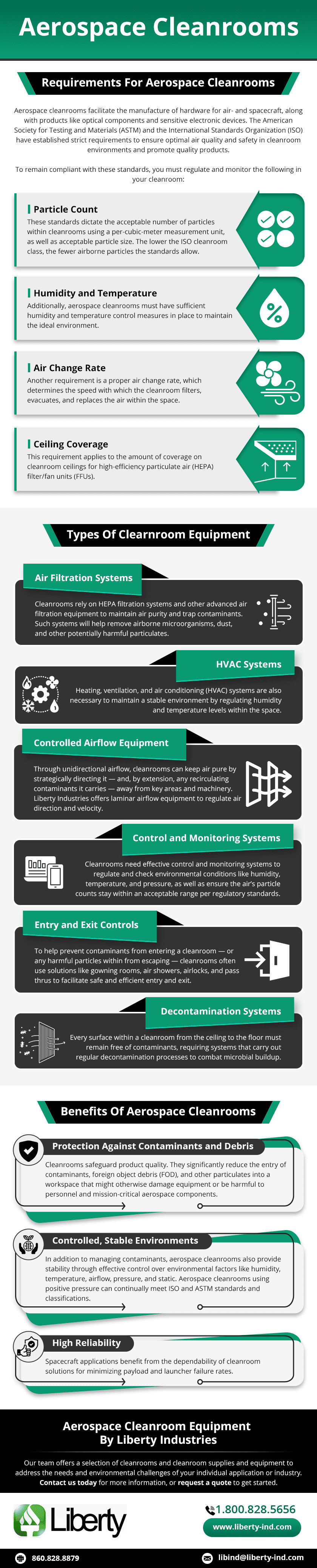

Requirements for Aerospace Cleanrooms

Aerospace cleanrooms facilitate the manufacture of hardware for air- and spacecraft, along with products like optical components and sensitive electronic devices. The American Society for Testing and Materials (ASTM) and the International Standards Organization (ISO) have established strict requirements to ensure optimal air quality and safety in cleanroom environments and promote quality products.

ASTM has established cleanroom cleanliness standards with the goal of minimizing contamination in these spaces. The society’s International Standards for testing help ensure that only a specified number of particles exist within cleanroom air.

As for ISO, this organization implemented the ISO 14644-1 standard that covers cleanroom environment regulations. This standard classifies cleanrooms into various cleanliness levels ranging from Class 1 to 9. At Class 9, cleanrooms have the air cleanliness of typical room air, while Class 1 cleanrooms achieve the cleanest air possible. Typically, aerospace cleanrooms must operate as Classes 7 or 8.

To remain compliant with these standards, you must regulate and monitor the following in your cleanroom:

- Particle count. These standards dictate the acceptable number of particles within cleanrooms using a per-cubic-meter measurement unit, as well as acceptable particle size. The lower the ISO cleanroom class, the fewer airborne particles the standards allow.

- Humidity and temperature. Additionally, aerospace cleanrooms must have sufficient humidity and temperature control measures in place to maintain the ideal environment.

- Air change rate. Another requirement is a proper air change rate, which determines the speed with which the cleanroom filters, evacuates, and replaces the air within the space.

- Ceiling coverage. This requirement applies to the amount of coverage on cleanroom ceilings for high-efficiency particulate air (HEPA) filter/fan units (FFUs).

Types of Cleanroom Equipment

Cleanrooms for applications in aerospace utilize an array of equipment and systems to preserve air quality and necessary workspace conditions. Examples include the following:

- Air filtration systems. Cleanrooms rely on HEPA filtration systems and other advanced air filtration equipment to maintain air purity and trap contaminants. Such systems will help remove airborne microorganisms, dust, and other potentially harmful particulates.

- HVAC systems. Heating, ventilation, and air conditioning (HVAC) systems are also necessary to maintain a stable environment by regulating humidity and temperature levels within the space.

- Controlled airflow equipment. Through unidirectional airflow, cleanrooms can keep air pure by strategically directing it — and, by extension, any recirculating contaminants it carries — away from key areas and machinery. Liberty Industries offers laminar airflow equipment to regulate air direction and velocity.

- Control and monitoring systems. Cleanrooms need effective control and monitoring systems to regulate and check environmental conditions like humidity, temperature, and pressure, as well as ensure the air’s particle counts stay within an acceptable range per regulatory standards.

- Entry and exit controls. To help prevent contaminants from entering a cleanroom — or any harmful particles within from escaping — cleanrooms often use solutions like gowning rooms, air showers, airlocks, and pass thrus to facilitate safe and efficient entry and exit.

- Decontamination systems. Every surface within a cleanroom from the ceiling to the floor must remain free of contaminants, requiring systems that carry out regular decontamination processes to combat microbial buildup.

All tools, systems, and materials within a cleanroom should be non-porous when possible to facilitate regular cleanings and discourage microbial growth. Similarly, they should withstand degradation when exposed to cleansers and cleaning processes.

In addition to cleanroom equipment, Liberty Industries also offers cleanroom and lab supplies like disposable and protective apparel, wipes, mats, HEPA filter vacuums, specialized cleaners, and various other maintenance products.

Benefits of Aerospace Cleanrooms

Cleanrooms deliver numerous advantages that make them worth implementing in aerospace environments, including:

- Protection against contaminants and debris. Cleanrooms safeguard product quality. They significantly reduce the entry of contaminants, foreign object debris (FOD), and other particulates into a workspace that might otherwise damage equipment or be harmful to personnel and mission-critical aerospace components.

- Controlled, stable environments. In addition to managing contaminants, aerospace cleanrooms also provide stability through effective control over environmental factors like humidity, temperature, airflow, pressure, and static. Aerospace cleanrooms using positive pressure can continually meet ISO and ASTM standards and classifications.

- High reliability. Spacecraft applications benefit from the dependability of cleanroom solutions for minimizing payload and launcher failure rates.

Aerospace Cleanroom Equipment by Liberty Industries

Aerospace Cleanroom Equipment by Liberty Industries

If you’re looking for reliable, high-quality cleanroom and equipment solutions to maintain environmental conditions in your operation, the contamination control experts at Liberty Industries can help. Our team offers a selection of cleanrooms and cleanroom supplies and equipment to address the needs and environmental challenges of your individual application or industry. Contact us today for more information, or request a quote to get started.