Cleanrooms are tightly controlled spaces that contain ultra-low concentrations of airborne particles. They protect operations that are sensitive to certain temperatures, dust, dirt, moisture, and other environmental conditions.

A portable cleanroom is one of the most popular types of cleanroom. This versatile solution is customizable to each organization’s unique dimensional and operational needs. Liberty Industries manufactures and distributes quality cleanrooms to a global customer base. We have an experienced technical team to help our customers get cleanrooms that meet their specifications.

WHAT IS A PORTABLE CLEANROOM?

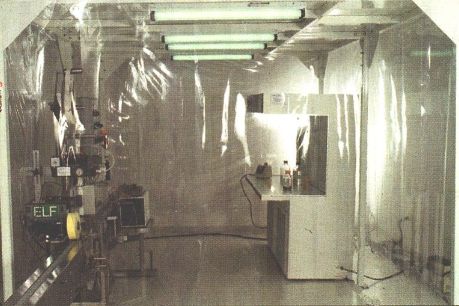

A portable or modular cleanroom is a prefabricated isolation enclosure assembled and installed onsite. The customer can easily expand or relocate the cleanroom as needed. There are two main types of portable cleanrooms: softwall and hardwall.

SOFTWALL MODULAR CLEANROOMS

Softwall modular cleanrooms offer an easy solution for production operations in small- to medium-sized areas. They are easy to assemble, lightweight, and cost-effective.

With soft walls, these cleanrooms are quick and easy to expand or contract without disassembling and reinstalling the entire cleanroom. It is fast and easy to adjust the shape or add sections to the cleanroom to fit your requirements. You can also combine multiple smaller rooms to create a larger cleanroom area. Softwall modular cleanrooms are available in different classes, from Class 100,000 to Class 10.

Modular softwall cleanrooms are ideal for companies or institutions that need a simple, immediate solution to conduct part of their operations in a cleanroom environment. Modular softwall cleanrooms are commonly used as positive pressure enclosures. However, they can be installed alongside a HEPA filter if there is a need for negative pressure containment.

Investing in a modular softwall cleanroom gives you a highly flexible choice in terms of functionality, adaptability, and affordability.

HARDWALL MODULAR CLEANROOMS

Modular hardwall cleanrooms are durable and impact-resistant structures. The free-standing vertical laminar flow systems offer excellent cleanroom quality as well as aesthetic appeal. Their rigid walls allow them to operate at higher internal pressures than softwall modular cleanrooms. Hardwall modular cleanrooms range from Class 100,000 to Class 10.

WHAT ARE THE BENEFITS OF PORTABLE/MODULAR CLEANROOMS?

There are many benefits of portable cleanrooms, such as their modular capabilities. Customers can quickly and easily repurpose or expand the cleanroom depending on changing needs, all with little onsite disruption. In contrast, standard-built cleanrooms within a facility can take months to set up and install.

Whether you opt for a softwall or hardwall modular cleanroom, it will maintain a high level of performance and value throughout its service life. Here are the specific benefits of softwall and hardwall cleanrooms.

BENEFITS OF SOFTWALL CLEANROOMS

- Cost-effective: Modular softwall cleanrooms cost less than hardwall types. They have a minimalist design that requires fewer materials and tools to construct. This also means you will need fewer workers to get the cleanroom up and operational. They can meet the same class specifications as hardwall cleanrooms—Class 100,000 to 10—at a lower cost.

- Available in different shapes and sizes: Due to the different operations and equipment used across industries, a cleanroom with a fixed shape and size can be limiting. Modular softwall cleanrooms are available in different shapes and sizes, so companies have the freedom to choose one according to their specific needs.

- Adjustable without reinstallation: When operational needs change, you may want to reduce or expand the size of your cleanroom. With modular softwall cleanrooms, you can adjust the size without having to reinstall.

- Easy to add or remove sections: Softwall modular cleanrooms allow you to add or remove sections quickly.

- Allows mobile construction: If you need a mobile cleanroom solution, softwall cleanrooms can be equipped with casters to facilitate mobile construction.

- Customizable to various specifications: Modular softwall cleanrooms can be constructed to your required specifications without compromising quality.

BENEFITS OF HARDWALL CLEANROOMS

- Excellent visual appeal and visibility: Modular hardwall cleanrooms are typically made with clear anodized panels that offer good visibility and aesthetic appeal. Good visibility is crucial to personnel working in and around cleanrooms.

- Easy to combine multiple rooms or sections: When an operation’s needs change, you can simply combine multiple rooms to increase the size of your cleanroom without assembling a larger one.

- Wall dampers help regulate pressure: Modular hardwall cleanrooms are equipped with wall dampers, which are more effective at helping regulate pressure inside the enclosure.

- Comes with a single pass or closed loop airflow recirculation: Modular hardwall cleanrooms have the option to use a single pass design, where air is filtered into the cleanroom and then released to the surrounding environment. Alternatively, it can come with a closed loop design, which recirculates filtered and conditioned air continuously within the enclosure.

- Easy to disassemble and relocate: You may construct a cleanroom in a certain location but later want to change it due to changes in your operational needs. Once you build a modular hardwall cleanroom, you can easily modify, dismantle, and relocate it.

- Wall support posts for gas and electrical connections: Depending on the operation, the cleanroom may need gas and power supply. Modular hardwall cleanrooms have rigid wall support posts, providing a secure surface to run gas, electrical, or low-voltage connections.

SERVICES OFFERED BY LIBERTY INDUSTRIES

At Liberty Industries, we offer a wide range of services related to cleanrooms. Our experienced and skilled technical team understands various industry cleanroom requirements to ensure you receive the exact solution you need.

Our services include:

- Cleanroom planning

- Construction & installation

- Design & build

- Differential pressure qualification

- Dispersed oil particulate (DOP) testing

- Smoke testing

- Third party cleanroom certification

- Training & support

- Alterations/modifications

INDUSTRIES WE SERVE

Modular cleanrooms can be found in nearly every industry, including the medical devices, defense, pharmaceutical, food and beverage, semiconductor, aerospace, government, E-liquid, and industrial sectors. They cost about the same as standard-built cleanrooms but have more flexibility and faster installation.

MODULAR/PORTABLE CLEANROOMS FROM LIBERTY INDUSTRIES

Modular cleanrooms are necessary to protect critical processes and environments. The structures are increasingly becoming popular in various industries due to their quick installation, easy maintenance, and high degree of customizability. They meet operational requirements just like traditional structures but come with additional versatility.

If you are looking to protect your critical processes and increase value in your operations with modular cleanrooms, you need to partner with an experienced company with a proven track record of building structures that guarantee efficiency and integrity. At Liberty Industries, we have over 60 years of experience designing and building modular cleanrooms, air showers, shoe brush machines, laminar flow benches, and more.

WHAT ARE CLEANROOM REQUIREMENTS?

Cleanrooms have various requirements, the most common ones including the size, number of rooms, ceiling height, temperature, humidity, chemical resistance, and flooring.

Contact us today or request more information to learn more.