Cleanroom Air Showers

Liberty Industries is a leading provider of high-quality cleanrooms and equipment for commercial and industrial applications. For over 70 years, our company has manufactured cleanrooms that incorporate the latest technologies and best practices to ensure a clean, contamination-free space that exceeds standard requirements. Choose Liberty Industries for cleanrooms, contamination control supplies, and a trusted partner for ongoing cleanroom support. If you’re thinking about augmenting your cleanroom with an air shower, read through this guide so you know what to look for and how to choose the right unit for your organization.

View Our Cleanroom Air Showers Catalog

What Are Cleanroom Air Showers and How Do They Work?

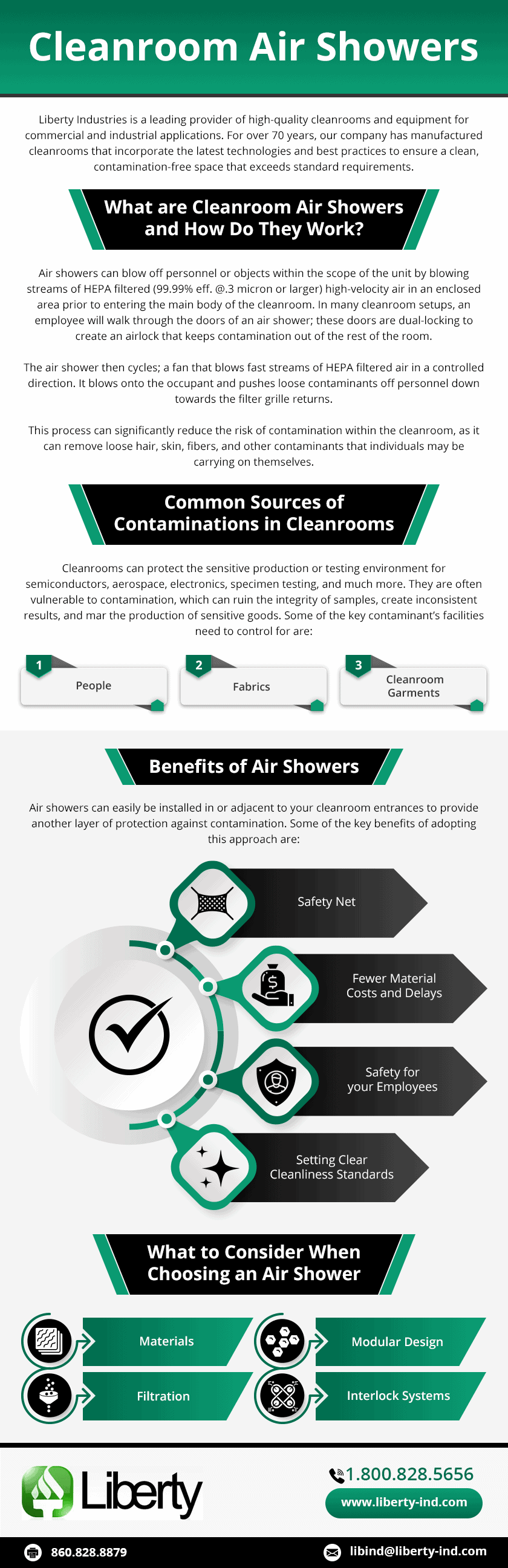

Air showers can blow off personnel or objects within the scope of the unit by blowing streams of HEPA filtered (99.99% eff. @.3 micron or larger) high-velocity air in an enclosed area prior to entering the main body of the cleanroom. In many cleanroom setups, an employee will walk through the doors of an air shower; these doors are dual-locking to create an airlock that keeps contamination out of the rest of the room. The air shower then cycles; a fan that blows fast streams of HEPA filtered air in a controlled direction. It blows onto the occupant and pushes loose contaminants off personnel down towards the filter grille returns. This process can significantly reduce the risk of contamination within the cleanroom, as it can remove loose hair, skin, fibers, and other contaminants that individuals may be carrying on themselves.

Cleanroom air showers are increasingly common because of their effectiveness, fast, and cost-effective ability to minimize and reduce contamination risks.

Common Sources of Contamination in Cleanrooms

Cleanrooms can protect the sensitive production or testing environment for semiconductors, aerospace, electronics, specimen testing, and much more. They are often vulnerable to contamination, which can ruin the integrity of samples, create inconsistent results, and mar the production of sensitive goods. Some of the key contaminant’s facilities need to control for are:

- People: Hair, particles of skin, sweat, and dirt are all common contaminants that people can introduce to an unprotected space. Facilities may control this risk by having a cleanroom, using an air shower, and/or having employees wear cleanroom gowns, hoods, or complete suits that create a physical barrier between the person and the work environment.

- Fabrics: Natural fabrics such as wool, cotton, and linen are popular for clothing, but they’re made up of thousands of small fibers that can break away and hang in the air before landing on products or specimens. Even more concerning, those fibers have a rough surface that makes them difficult to remove from the surface of items.

- Cleanroom garments: Over time, even the protective reusable cleanroom garments can collect contaminants that will spread across the closed environment without intervention. A cleanroom air shower can help reduce those contaminant’s so the garments are effective with fewer cleaning cycles.

What Are Benefits of Air Showers?

Air showers can easily be installed in or adjacent to your cleanroom entrances to provide another layer of protection against contamination. Some of the key benefits of adopting this approach are:

- Safety net: People make mistakes and may accidentally increase the risk of contaminants within a cleanroom by skipping a step in entrance and exit policies. However, an automatic operation cleanroom air shower removes those incident particles and contaminants.

- Fewer material costs and delays: Contamination can ruin samples and sensitive products. By proactively preventing sources of contamination, you reduce the risk that batches of goods will fail quality standards.

- Safety for your employees: By removing potentially harmful particles, air showers can help to improve the overall safety of cleanroom personnel.

- Setting clear cleanliness standards: Air showers reinforce the seriousness of contamination and high cleanliness standards within your facility. Employees will have regular reminders to take more care because of the measures in place.

What to Consider When Choosing an Air Shower

As you shop around for the right cleanroom air shower for your facility’s needs, consider these factors:

- Materials: Constructed in stainless steel shell or ¾” novaply laminated with high pressure plastics as options to consider.

- Modular design: Modular air showers can be easily shipped and installed within existing cleanrooms.

- Filtration: Opt for systems that use both pre-filters and HEPA filters .

- Interlock systems: Choose more secure systems with controllable magnetic door interlock features.

Talk to Liberty Industries Today About Cleanroom Air Showers

At Liberty Industries, we manufacture and deliver air showers for use in biotech, medical, microelectronic and nanotechnology, optics, pharmaceutical, and aerospace industries, among others. Contact us today online or over the phone at 1.800.828.5656 to learn more about the value of adding an air shower to your facilities, or request a quote to start your order.