Medical Cleanrooms

Medical device and pharmaceutical manufacturers, hospitals, and government laboratories all use medical cleanrooms as they provide strictly controlled environments for research and development, production, and testing. Medical cleanrooms promote safety and meet high standards for minimizing cross-contamination by managing airflow, keeping airborne particles out of the work area, and controlling multiple aspects of the environment.

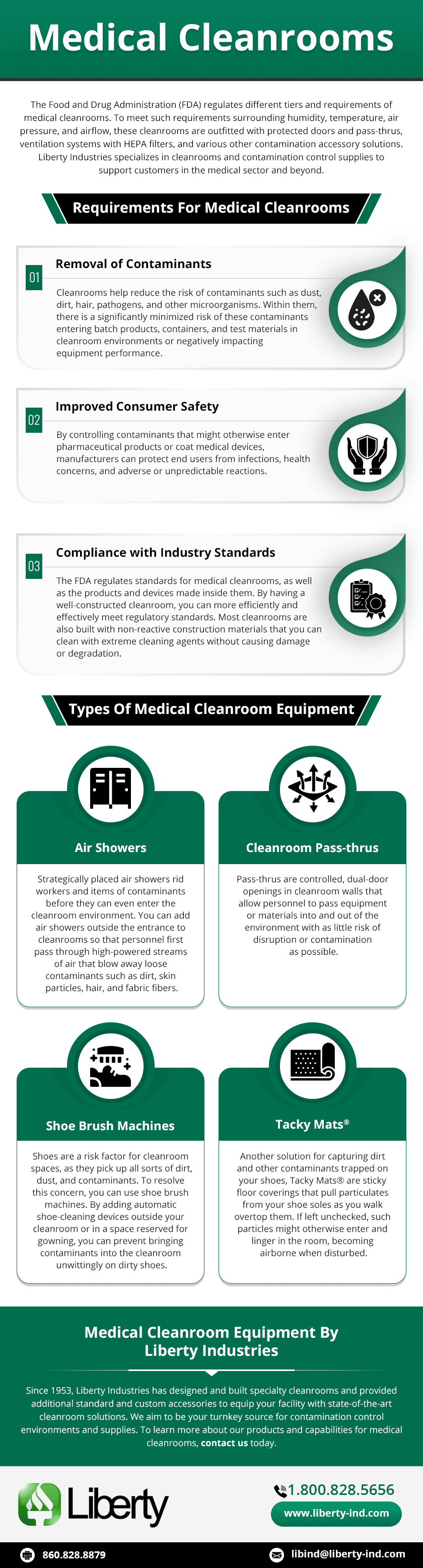

The Food and Drug Administration (FDA) regulates different tiers and requirements of medical cleanrooms. To meet such requirements surrounding humidity, temperature, air pressure, and airflow, these cleanrooms are outfitted with protected doors and pass-thrus, ventilation systems with HEPA filters, and various other contamination accessory solutions. Liberty Industries specializes in cleanrooms and contamination control supplies to support customers in the medical sector and beyond.

Requirements for Medical Cleanrooms

Medical cleanrooms are crucial in producing high-quality medical devices and safe pharmaceutical goods. They offer several advantages over traditional manufacturing or laboratory environments, including the following:

- Removal of contaminants. Cleanrooms help reduce the risk of contaminants such as dust, dirt, hair, pathogens, and other microorganisms. Within them, there is a significantly minimized risk of these contaminants entering batch products, containers, and test materials in cleanroom environments or negatively impacting equipment performance.

- Improved consumer safety. By controlling contaminants that might otherwise enter pharmaceutical products or coat medical devices, manufacturers can protect end users from infections, health concerns, and adverse or unpredictable reactions.

- Compliance with industry standards. The FDA regulates standards for medical cleanrooms, as well as the products and devices made inside them. By having a well-constructed cleanroom, you can more efficiently and effectively meet regulatory standards. Most cleanrooms are also built with non-reactive construction materials that you can clean with extreme cleaning agents without causing damage or degradation.

Types of Medical Cleanroom Equipment

Medical device cleanroom environments, on their own, can significantly increase the safety and efficacy of medical products. At Liberty Industries, we also produce supplemental tools and safety equipment to further minimize the risk of contaminants and give you more control of your production environment.

Air Showers

Strategically placed air showers rid workers and items of contaminants before they can even enter the cleanroom environment. You can add air showers outside the entrance to cleanrooms so that personnel first pass through high-powered streams of air that blow away loose contaminants such as dirt, skin particles, hair, and fabric fibers.

Cleanroom Pass-Thrus

Pass-thrus are controlled, dual-door openings in cleanroom walls that allow personnel to pass equipment or materials into and out of the environment with as little risk of disruption or contamination as possible. The doors include mechanical or electronic interlock features so only one door can open at a time, granting you more control over airflow and environmental conditions. For example, you can more easily maintain a pressurized environment that pushes back against potentially contaminated air.

Shoe Brush Machines

Shoes are a risk factor for cleanroom spaces, as they pick up all sorts of dirt, dust, and contaminants. To resolve this concern, you can use shoe brush machines. By adding automatic shoe-cleaning devices outside your cleanroom or in a space reserved for gowning, you can prevent bringing contaminants into the cleanroom unwittingly on dirty shoes.

Tacky Mats®

Another solution for capturing dirt and other contaminants trapped on your shoes, Tacky Mats® are sticky floor coverings that pull particulates from your shoe soles as you walk overtop them. If left unchecked, such particles might otherwise enter and linger in the room, becoming airborne when disturbed.

Medical Cleanroom Equipment by Liberty Industries

Using a medical cleanroom is vital not only for enhancing product and device quality but also for ensuring patient, worker, and consumer safety. These spaces also support regulatory compliance with the FDA. Since 1953, Liberty Industries has designed and built specialty cleanrooms and provided additional standard and custom accessories to equip your facility with state-of-the-art cleanroom solutions. We aim to be your turnkey source for contamination control environments and supplies. To learn more about our products and capabilities for medical cleanrooms, contact us today.