Cleanroom HVAC Systems 101

Founded in 1953, Liberty Industries has since established itself as a premier manufacturer and distributor of cleanroom and contamination control supplies and accessories. Equipped with almost seven decades of industry experience, we can design, build, and install some of the highest quality cleanrooms with top-of-the-line components, including cleanroom HVAC systems.

The following blog post provides an overview of HVAC systems for cleanrooms, outlining design basics and key design considerations.

The Basics of HVAC Design

Heating, ventilation, and air conditioning (HVAC) is an umbrella term for the systems used to maintain conditions—e.g., temperature, airflow, and humidity—within indoor areas. They are used in industrial, commercial, and residential facilities to ensure environmental conditions are comfortable and optimal for the necessary operations. When integrated into cleanrooms, they are critical to the maintenance of air quality levels for applications involving sensitive materials or requiring the containment of potentially hazardous materials.

Conventional and cleanroom HVAC systems have some overlapping functions—i.e., enabling industry professionals to control temperature, humidity, and airflow to achieve comfortable living and working conditions. However, the HVAC systems for cleanrooms also perform more advanced functions—such as monitoring and maintaining air supply and flow patterns, filtering out contaminations, and preserving pressure differentials—to ensure the enclosed area is suitable for sensitive and/or dangerous material operations.

The design of a cleanroom HVAC system changes depending on the requirements and restriction of the application, including ISO classification , temperature, humidity, and pressure specifications. Some of the key components include:

- Air handling units (AHUs)

- Air ducts

- High-efficiency particulate air (HEPA) filters

- Air diffusers

- Air return pathways and equipment

- Air quality monitoring and control systems

Considerations During the Design Phase

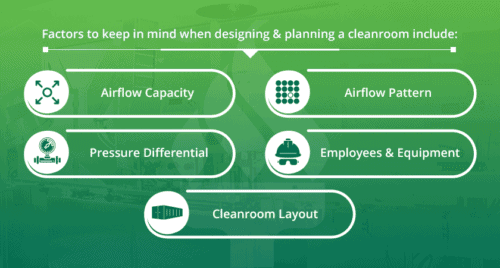

When designing and planning a cleanroom, there are several factors to keep in mind to ensure the finished structure meets the needs of the application. While designs may vary depending on the operations performed within the cleanroom some of the key considerations include:

Airflow Capacity

The airflow capacity of a cleanroom (indicated in cubic feet per minute) affects how many air changes are performed per hour. This characteristic, in turn, depends on several factors, such as the cleanliness level required, the number of personnel and equipment/supplies, the size and number of rooms, and the movement of the people and materials into and out of the cleanroom. While commercial HVAC systems perform less than two air changes per hour, cleanroom HVAC systems generally do 10 to 600 air changes per hour. The higher air change frequency is necessary to prevent particles from settling in the cleanroom.

Airflow Pattern

Airflow patterns within cleanrooms generally take one of three forms: laminar (unidirectional), turbulent (non-directional), or mixed-flow. The pattern appropriate for a cleanroom depends on the design and application.

Pressure Differential

Cleanrooms are available in positive pressure or negative pressure variations. Positive pressure cleanrooms are used to keep contaminants out, while negative pressure cleanrooms are designed to keep potentially hazardous materials in.

Employees and Equipment

Both employees and equipment are sources of contamination for cleanrooms. When brought in or out, they may allow particulates and pollutants to come into the controlled environment or hazardous materials to escape into the outside environment. With this in mind, cleanroom personnel must commit to rigorous health and safety protocols such as wearing the correct personal protective equipment (PPE), going through decontamination areas and bringing in or out only cleared supplies and materials.

Other factors that employees influence include the number of air changes required per hour (more employees mean more air changes) and the temperature levels (cleanroom temperature must be within comfortable levels for human operators).

Cleanroom Layout

The layout of a cleanroom affects the efficiency and effectiveness of the HVAC system. For example, the positioning of equipment and air input/output points can help or hinder the filtration of particulates.

Design and Construct Your Cleanroom With Liberty Industries

For all your cleanroom needs, turn to the experts at Liberty Industries. We provide cleanroom design, construction, and installation services as well as all related supplies and accessories to deliver a complete solution.

For additional information about our cleanroom capabilities, download our eBook or contact us today. To receive pricing details, request a quote with your cleanroom requirements.