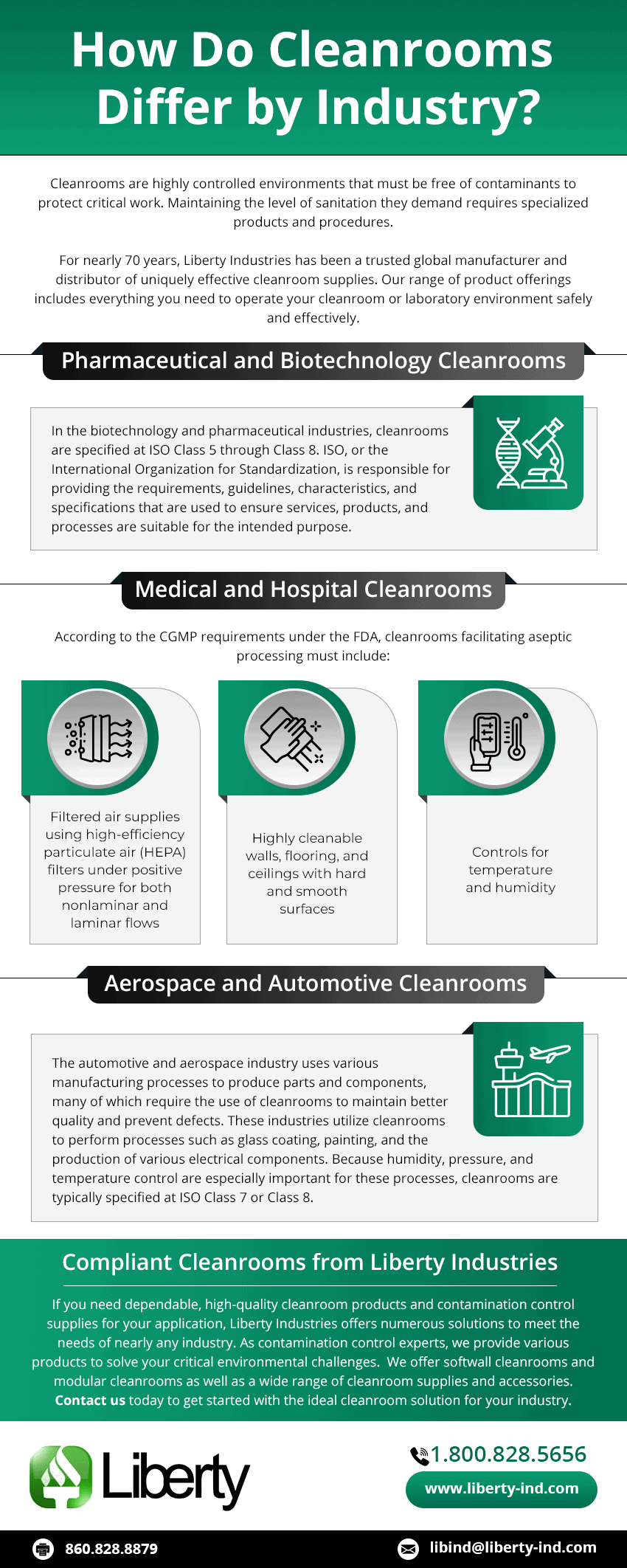

How Do Cleanrooms Differ by Industry?

Leave a CommentNot all cleanrooms are created equally. Depending on the particular industry, cleanroom classifications and specifications vary, as different manufacturing processes have unique standards and sterility requirements. Here, we’ll take a look at the various industries that rely on cleanrooms and how each one differs.

Pharmaceutical and Biotechnology Cleanrooms

In the biotechnology and pharmaceutical industries, cleanrooms are specified at ISO Class 5 through Class 8. ISO, or the International Organization for Standardization, is responsible for providing the requirements, guidelines, characteristics, and specifications that are used to ensure services, products, and processes are suitable for the intended purpose.

Particulate matter is the primary concern for any cleanroom, specifically when it comes to viable particulate contamination. It’s possible to prevent viable particulate contamination by installing cleanrooms with cove corners, cove ceilings, and cove bases in stick-built or modular designs, all of which help to maintain cleanable surface conditions. These design elements are especially crucial for meeting cleanroom standards for biotechnology and pharmaceutical applications.

Cleanrooms in the pharmaceutical and biotechnology industries prioritize the prevention of cross-contamination, filtration of indoor and outdoor air, and pressurization control. Because these cleanrooms are used to produce drugs and other pharmaceutical products, they must meet stringent guidelines and comply with regulations set forth by the FDA, including Current Good Manufacturing Practice (CGMP) requirements.

According to the CGMP requirements under the FDA, cleanrooms facilitating aseptic processing must include:

- Controls for temperature and humidity

- Highly cleanable walls, flooring, and ceilings with hard and smooth surfaces

- Filtered air supplies using high-efficiency particulate air (HEPA) filters under positive pressure for both nonlaminar and laminar flows

Medical/Hospital Cleanrooms

Cleanrooms in medical and hospital applications must meet many of the same requirements as those in the biotechnology and pharmaceutical industries to avoid contamination. Medical and hospital cleanrooms are specifically designed with cross-contamination in mind, incorporating cleanable surfaces and filters that prevent particulates from entering. In addition, professionals working in these cleanrooms must wear the proper apparel, including gloves, plastic clothing, hairnets, and shoe coverings. This protective gear can help maintain a safe environment that prevents bacteria from infecting patients.

Many cleanrooms in the medical industry function as isolation rooms for patients. These spaces require negative pressure that prevents the spread of contaminants between rooms caused by breathing, coughing, or sneezing. To avoid contamination, medical cleanrooms don’t allow for circulating air, and they utilize HEPA filters, alarms that detect any loss of pressure, and hands-free toilets and showers. The HEPA filters in these applications can remove dust and other particles as small as 0.3 µm.

Some specific applications for medical and hospital cleanrooms include the following:

- RNA / MRNA research

- Laboratory, veterinary, and hospital pharmacies

- Isolation wards

- T-cell and gene

- Medical equipment, devices, and tooling

Aerospace & Automotive Industry

The automotive and aerospace industry uses various manufacturing processes to produce parts and components, many of which require the use of cleanrooms to maintain better quality and prevent defects. These industries utilize cleanrooms to perform processes such as glass coating, painting, and the production of various electrical components. Because humidity, pressure, and temperature control are especially important for these processes, cleanrooms are typically specified at ISO Class 7 or Class 8.

Many vehicle components require specialized manufacturing processes that can’t be performed on factory lines. As vehicles become more technologically advanced, their components become increasingly delicate and small. These tiny components are critical to vehicle safety and operation; therefore, defective parts can lead to costly and dangerous accidents. As such, the need for automotive and aerospace cleanrooms has grown.

Cleanrooms in these industries not only can reduce errors but also allow for temperature and humidity control as well as the reduction in particulate, pressure, and static levels. Reliable cleanrooms also maintain foreign object debris (FOD) control, which has become increasingly critical in this industry.

Compliant Cleanrooms from Liberty

If you need dependable, high-quality cleanroom products and contamination control supplies for your application, Liberty Industries offers numerous solutions to meet the needs of nearly any industry. As contamination control experts, we provide various products to solve your critical environmental challenges. We offer softwall cleanrooms and modular cleanrooms as well as a wide range of cleanroom supplies and accessories.

Contact us today to get started with the ideal cleanroom solution for your industry.