Effective Cleanroom Building: A “Don’t-Do-It-Yourself” Project

Leave a Comment

Where did the rapid expansion of this mentality come from? The difficult economic times of the past few years play a role, to be sure, and so does the sheer volume of Complete Idiot’s Guide manuals in stock online and on bookshelves. And if those kinds of books don’t do the trick for you, you can watch a YouTube video or read an eHow article and have all your home improvement questions answered in a few minutes. While we at Liberty Industries have no problem in theory with this sort of problem-solving, we also know from years of personal experience that a DIY approach can’t come close to successfully building a facility as complex as a fully-functioning cleanroom.

Just as building a rocket that can make it into space requires an actual team of rocket scientists, building a cleanroom requires a qualified cleanroom design engineer. This engineer and anyone working under his or her supervision must be alert to any challenges and difficulties that lie between receiving a design and list of requirements, and successful completion of the cleanroom.

The design and construction team’s expertise also is not limited strictly to knowledge of contaminants – they wear many hats. They must be literate and experienced in the design of HVAC systems, and how those systems contribute to the successful

We certainly do not mean to discourage thoughtful “do-it-yourself” design in general. Out-of-the-box thinking certainly has useful and essential applications. That being said, the science of cleanroom design and fabrication is tried and true, but remains a challenge to many who would attempt it. With many decades of experience in this field under our belt, we at Liberty Industries do feel entitled to say it: leave expertise to the experts. You’ll never regret the results.

A New Item for Laboratories: the PureSeal Pass-Thru Unit

Leave a CommentSince 1953, Liberty Industries has been in the business of designing, building, and perfecting new contamination control technologies and strategies. Through nearly six decades of careful and consistent effort, we have accumulated a time-tested track record in building products that assure the necessary contamination controls in work environments that require them. Products that started out as one-time, custom designs have developed gradually into whole lines with a host of specific applications.

One product line that we are especially proud of fabricating is our new PureSeal Pass-Thru series. Pass-thrus are an existing technology, and basically operate hand-in-hand with a

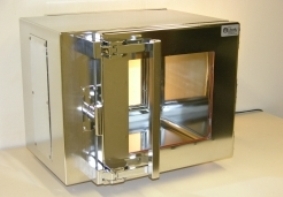

Liberty’s PureSeal Pass-Thru is intended for use in such areas as research university and biotechnology laboratory settings. Applying lessons learned over many years, the PureSeal performs its task of keeping exterior contaminants away from the interior cleanroom environment. Comprised entirely of easy-to-disinfect, electropolished 304 stainless steel, and employing a custom monolithic PureSeal gasket that allows for steam cleaning, the PureSeal is uncompromising in terms of its protective ability. An isolated mechanical interlock adds one more line of contaminant separation, ensuring that the interior and exterior doors of the PureSeal can never be open at the same time.

Help us to do a better job in providing innovative, state of the art products for scientific research and development. Feel free at any time to contact us with suggestions or just to let us know how you’ve applied our products to perform your job.