The Role of Stainless Steel in Cleanroom Equipment

Leave a CommentSince 1953, Liberty Industries has been manufacturing and distributing high-quality cleanroom and contamination control supplies and accessories across the globe. We are your one-stop source for all your cleanroom needs, offering products designed to meet the requirements of various critical environments.

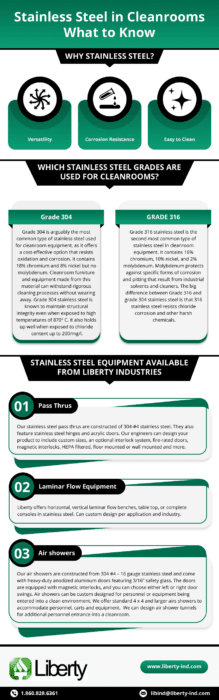

Stainless steel offers a range of properties that are specifically beneficial to cleanroom environments, making it an ideal material for various equipment. We offer stainless steel air showers, pass thrus, and laminar flow equipment that can be customized to fit your specific cleanroom needs.

Why Stainless Steel?

Stainless steel equipment and furniture are mostly preferred for cleanroom environments because they meet stringent hygienic requirements and safety standards. Stainless steel is not only robust and sturdy, but it can also withstand even the most rigorous cleaning processes. Some of the advantages of stainless steel equipment in cleanroom environments include:

- Versatility. Stainless steel is versatile when it comes to design, allowing stainless steel equipment manufacturers to provide tailor-made solutions complying with various regulatory criteria.

- Corrosion resistance. High-grade austenitic stainless steel, such as Grade 304, offers unmatched corrosion resistance to various chemicals, acids, and alkali.

- Easy to clean. Stainless steel is easy to clean and disinfect without the risk of losing its robustness and other properties. Grade 304 steel has no pores or cracks that could house dirt, grime, or bacteria. It cleans easily with soap and water, and it can also withstand more rigorous cleaning processes without corroding.

Which Stainless Steel Grades Are Used for Cleanrooms?

Some of the grades of steel often used for cleanroom equipment include:

Grade 304

Grade 304 is arguably the most common type of stainless steel used for cleanroom equipment, as it offers a cost-effective option that resists oxidation and corrosion. It contains 18% chromium and 8% nickel but no molybdenum. Cleanroom furniture and equipment made from this material can withstand rigorous cleaning processes without wearing away. Grade 304 stainless steel is known to maintain structural integrity even when exposed to high temperatures of 870° C. It also holds up well when exposed to chloride content up to 200/mg/l.

Grade 316

Grade 316 stainless steel is the second most common type of stainless steel in cleanroom equipment. It contains 16% chromium, 10% nickel, and 2% molybdenum. Molybdenum protects against specific forms of corrosion and pitting that result from industrial solvents and cleaners. The big difference between Grade 316 and grade 304 stainless steel is that 316 stainless steel resists chloride corrosion and other harsh chemicals.

Cleaning Stainless Steel in a Cleanroom

Some of the tips for cleaning and caring for stainless steel in cleanrooms include:

- Use warm water and a soft cloth or non-abrasive sponge to clean normal spills and small stains.

- Where necessary, use a mild soap or detergent to clean stainless steel surfaces.

- Use recommended solvents such as non-sterile or sterile 70% isopropyl alcohol to clean more stubborn messes such as grease, oil, stains, and fingerprints.

- Use a clean cloth over all surfaces to prevent water spots.

Stainless Steel Equipment Available from Liberty Industries

Liberty Industries provides various stainless steel cleanroom equipment designed to meet your specific needs. These include:

- Pass Thrus. Our stainless steel pass thrus are constructed of 304-#4 stainless steel. They also feature stainless steel hinges and acrylic doors. Our engineers can tailor-make your product to include custom sizes, an optional interlock system, fire-rated doors, and more.

- Laminar Flow Equipment. We offer stainless steel peripheral laminar flow cleanroom hoods and table top laminar flow fume hoods to protect against harmful fumes and contamination.

- Air showers. Our air showers are constructed from 304 #4 – 16 gauge stainless steel and come with heavy-duty anodized aluminum doors featuring 3/16″ safety glass. The doors are equipped with magnetic interlocks, and you can choose either left or right door swings.

Stainless Steel Cleanroom Equipment from Liberty Industries

Stainless steel is a very popular material option for various cleanroom equipment due to its many desirable properties and ability to withstand rigorous cleaning processes. At Liberty Industries, we offer durable stainless steel air showers, pass thrus, and laminar flow equipment that can be tailor-made for your specific cleanroom application. To learn more about our stainless steel cleanroom equipment, contact us today. You can also view our full catalog for more information about our other products.

Our Product Spotlight: Shoe Cleaners

Leave a CommentAs one of the leading contamination control experts, Liberty Industries has been known for providing high quality cleanroom and contamination control supplies to companies across the globe since 1953. We offer a large selection of products for many industries, including manufacturing facilities, pharmaceutical companies and healthcare companies.

John J, Nappi, Sr, founder of Liberty Industries, invented the shoe brush cleaner in the late 1960’s. It continues to be one of our most popular products since it can be used outside of cleanrooms as well as industrial applications. We were able to streamline the production process because we only source parts from US manufacturers instead of offshore suppliers. We proudly manufacture the shoe brush cleaner in the United States inside our state-of-the-art Connecticut facility.

Shoe Brush Cleaners for Your Cleanrooms & Controlled Environments

Labs, cleanrooms, and similar facilities require a clean environment that is free from contaminants. They are designed to maintain extremely low levels of particulates, including dust and airborne particles. Cleanrooms also usually have a level of cleanliness based on the number of particles per cubic meter at a predetermined molecule measure.

Facilities must follow certain protocols and buy multiple products to ensure that a specific room is clean enough. A motorized shoe cleaner for cleanrooms is an excellent investment, because it can remove dirt, dust, and other foreign substances from the soles of a worker’s shoes so that potentially dangerous contaminants can’t enter a cleanroom or laboratory environment. The innovative machine can also be placed either inside the gowning room or just outside of the cleanroom entrance. Many companies prefer shoe brush cleaners because they can efficiently clean the bottoms, sides, and tops of a person’s shoes.

Liberty Industries offers three primary models of shoe brush cleaners:

- Shoe Brush 2010SC

The Shoe Brush 2010SC model, which includes an optional Tacky Mat®, is a fully self-contained system that uses a timing belt between the gear motor and bottom brush assembly. The unit includes a HEPA filter exhaust system that allows it to operate at a 99.99% efficiency rate and is best used prior to entering a cleanroom area. It features an enclosed fan-cooled gear motor and a floating, weight-loaded top brush with a round belt drive and four motor-driven brushes. Workers are notified whenever the HEPA filters are dirty and the easily accessible contamination bag, pull-out dust drawers and filters make them easy to empty or replace.

- Shoe Brush 2001 – TB

The Shoe Brush 2001-TB model has four motor-driven brushes that allow it to clean both the sides, top, and bottom of a worker’s shoes. The 132-pound item, which can be used in a variety of settings both on and off-site, uses a transmission drive and an enclosed, fan-cooled motor.

- Shoe Brush 351 Bull Dog

The Shoe Brush 351 Bull Dog is a heavy duty machine that can quickly and efficiently clean mud, leaves, sand, and other debris that may stick to the bottom of someone’s shoes after they have walked around outside. Visitors and anyone else can use this machine when they come in and before they enter the facility’s office area.

Follow the Proper Maintenance Protocols

The Cleanroom Classification system is based on the number and size of contaminants within a room or space. The cleanrooms are ranked according to their level of sanitation as determined by the International Standards Organization (ISO), with Class 1 being the most sanitary, to Class 9, which is the least. The ISO standards have strict allowances for particles between 1μm and 5μm. The standards for a cleanroom will vary depending on the industry.

Facilities can reduce contamination and better maintain a controlled environment by maintaining strict hygiene measures, using protective equipment, using cleanroom supplies and ensuring that workers cautiously enter and exit the area. For this reason, products like a high quality shoe brush machine are important, because they can help reduce the risk of contaminants entering the work area.

Order High Quality Shoe Brush Machines From Liberty Industries!

Shoe brush cleaners are a smart investment for facilities in various industries. As one of the largest manufacturers and distributors of top quality cleanroom and contamination control supplies and accessories, Liberty Industries can be your main source for all your cleanroom needs. Feel free to view our product catalog, download our free eBook, and contact us for additional information about our high quality shoe brush machines.