A Guide to Cleanroom Cleaning & Maintenance

At Liberty Industries, we build high-quality cleanrooms with customizable designs. We offer myriad products to create specialized environments and offer complete installation services. Since 1953, we have been providing industrial companies comprehensive solutions and contamination control supplies, including those pertaining to cleanroom cleaning.

Cleanrooms use a variety of mechanisms to reduce the risk of contamination, such as vertical flow component systems for airflow and Tacky Mats® that capture dirt and dust. Regular cleaning and maintenance of cleanrooms ensures optimal operation so products don’t fail inspection and research results don’t become contaminated.

How to Clean a Cleanroom

Dirt, dust, and contaminants may enter even the most carefully controlled cleanroom as people enter and exit, with material shipments, and more. There are two main categories of contaminants: physical contaminants generated by the cleanroom itself, and process or human action contaminants from cleaning, the movement of goods, and particulates from skin and hair. Floors, work areas, walls, ceilings, and vents must be wiped down during and after each session to keep the environment sterile and secure.

Cleanroom floors can easily become contaminated over time as dust and other particulates settle. At Liberty Industries, we recommend that facilities regularly follow a comprehensive process to clean floors. This process should include the following:

- Vacuuming the surface to remove any loose dirt and debris.

- Next, rinse the floor with deionized water and a certified cleansing solution to break up films or dried contaminants.

- Once the floor is dry, vacuum it again to remove every trace of debris disturbed during the mopping process.

- For larger cleanrooms, it’s important to change the water between rooms or every 15 square feet to reduce the risk of cross-contaminating separate spaces.

Companies should also implement preventative measures to reduce contamination in the first place. These steps include Tacky Mats®, air showers, and shoe covers that keep debris from reaching the cleanroom environment in the first place.

The floor isn’t the only surface that suffers from contamination. It’s just as important to wipe down work surfaces, gowning areas and benches, pass-thrus, walls, and windows. Vertical surfaces can capture contaminants circulated through the air and may also become contaminated at high touch points.

We recommend using wipes and sponges that are specifically designed for cleanroom applications. These cleaning tools have less breakable fibers and are much less likely to create debris. Lint-free 70% IPA wipes, in particular, present minimal risk of debris. HEPA filter hand dryers are also available.

Liberty Industries distributes cleaning materials for a variety of different cleanroom environments. We carefully source and recommend products that help our customers maintain their cleanroom’s rating. Some of the products we provide include:

- LIB8312 Sterile IPA 30/70, 12 oz, 16/cs

- CRF440 Cleaning agent, 20 oz

- 8025 Econowipe, 9 x 9 wipes, 6 tubs/cs, 300 per tub

- LN-10 Urethane sponges

- HEPA filter vacuums such as our CRV 7347 model

Additional Cleanroom Maintenance

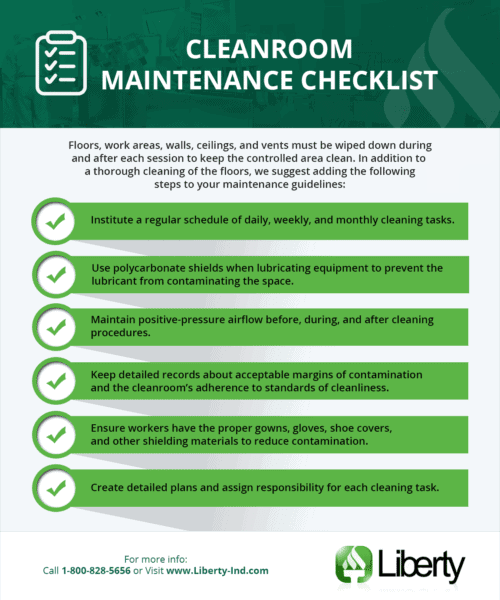

Keeping your cleanroom in spec should be one of your facility’s top priorities. Additional steps your team can take to ensure high-quality production and testing conditions include:

- Instituting a regular schedule of daily, weekly, and monthly cleaning tasks.

- Using polycarbonate shields when lubricating equipment that prevent the lubricant from contaminating the space.

- Maintaining positive-pressure airflow before, during, and after cleaning procedures.

- Keeping detailed records about acceptable margins of contamination and the cleanroom’s adherence to standards of cleanliness.

- Ensuring workers having the necessary gowns, gloves, shoe covers, and other shielding materials to reduce contamination during cleaning procedures.

- Create detailed plans and assign responsibility for each cleaning task so your cleanroom is never in violation of cleanliness standards.

Cleanroom Construction, Maintenance, and Support From Liberty

Cleanrooms require a lot of care and maintenance to keep them operating in accordance with regulations and industry standards. At Liberty Industries, we don’t just create and install cleanrooms. We can provide our customers with the tools and cleaning supplies to assist them in maintaining their required cleanroom needs.

Contact our team or request a quote for more information about best practices and leading products for cleanroom maintenance and cleaning.